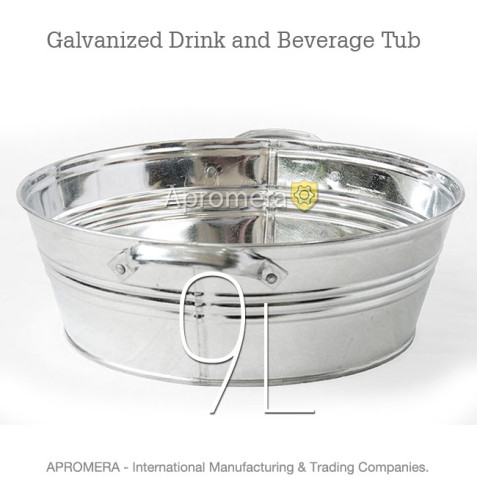

Galvanized Beverage Tub – 9 Liters

by manufacturer Apromera

This Round Galvanized Beverage tub for shoe storage, planting plants, an ice bucket, beverage tub, or even a place to put hats and scarves at the front door. This would be an excellent addition to add to the bar at a wedding reception. It can hold up to 6 bottles of wine. It's lightweight and comes with easy carry handles. Our tubs are very high quality. Product quality is controlled at all stages of production. Bucket Inspirations: Wine tub, Beverage tub, Wedding favors, Wedding programs, Wedding decor, Hostess Gift, Hold plenty of towels for guest bath or beach house, Great size for collection of all those winter accessories, Newspaper holder, Magazine holder.

Min. Order Quantity:

360 Piece/Pieces

Supply Ability:

40000 Piece/Pieces per Month

Specification

Product Name: Galvanized Beverage Tub

Capacity: 9 Litres (2 Gallons)

Dimensions:

Height: 14cm

Diameter at top: Ø 36cm

Diameter bottom: Ø 28cm

Approx. Net Weight: 0.820g

Material: Galvanized steel 0.5 mm. ArcelorMittal (Steel Grade DX51 + Zn120).

Packing Quantity: 10 pcs

Color: Silver (Galvanised Silver Zinc)

Long Lasting

Heavy Duty

Rust Free

1 Palette - 360 pcs

Delivery Detail: 25 days

Description

Our competitive (technological) advantages

Galvanized Round Beverage Tub – 9 Liters / Production

Reliability and quality of production (tested by the time)

We produce Galvanized Round Beverage Tub of steel with a thickness of 0.45 mm. -0.50 mm. Such production is considered to be a standard quality. It is more resistant to deformation and outside influences.

Handles type №1. The handles of the Galvanized Round Beverage Tub is made of 0.55 – 0.55 mm steel. This increases the lifetime of products and their capacity.

Handles type №2. In the production of galvanized round tubs we use the handle of galvanized wire Ø 5 – 6mm.

We have abandoned the method of welding the handles with the casing. For connection of the handles with the casing we use galvanized rivets with a diameter of 5.00 mm which provides a considerable strength and lack of rust in the joints.

The most important thing. By assembly of the buckets we do not use welding (we have abandoned it), and specifically: seaming the casing and calendering the bottom of the buckets are made on the seaming machines (at the seaming spot 3-4 metal layers are made up, depending on the product type), which increases the strength and leakage protection of the articles. This process is called rolling.

Producers usually use welding joints which are less strong and prone to oxidation. Such buckets develop leakage very soon (This has been checked by test control).