Description

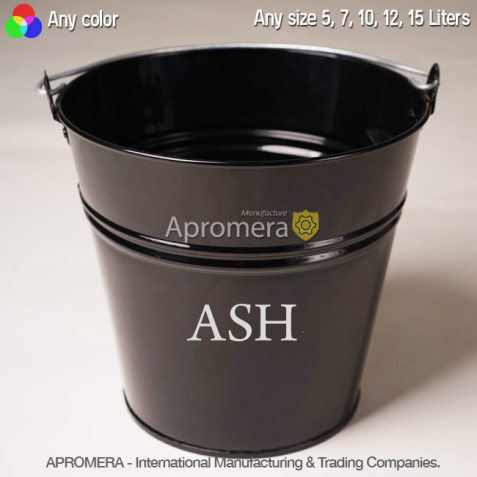

Production Metal Ash Buckets – 12 Liters.

Reliability and quality of production (tested by the time). Apromera only delivers services or products conforming to our strict quality standards. Quality is essential for gaining our customers’ trust in the long term.

Our factory produces Metal Ash Buckets of steel with a thickness of 0.35 to 0.55 mm.

High quality of handles

The diameter of handles (for 5, 7, 10, 12, 15L buckets) is 5.0mm. They are made of galvanized steel. Our handles are more comfortable because thicker handles do not cut hands. Additionally, we can install a plastic handle.

The lug of the Metal Ash Buckets is made of 0.45 – 0.50 mm steel. This increases the lifetime of products and their capacity.

Important! Our advantage

In the manufacture and assembly of the buckets we do not use welding and soldering, which lead to oxidation of the surface. All the joints are made with the help of seaming as well as using galvanized rivets, which further increases the strength of the products.

We have abandoned the method of welding the lugs with the casing. For connection of the lugs with the casing we use galvanized rivets with a diameter of 5.00 mm which provides a considerable strength and lack of rust in the joints.

Rolling – reliable technology

By assembly of the buckets we do not use welding (we have abandoned it), and specifically: seaming the casing and calendering the bottom of the buckets are made on the seaming machines (at the seaming spot 3-4 metal layers are made up, depending on the product type), which increases the strength and leakage protection of the articles. This process is called rolling.

Such buckets develop leakage very soon (This has been checked by test control). Producers usually use welding joints which are less strong and prone to oxidation.